The Materials of WELL being

- Lydia Tiasiri

- November 7, 2023

- Wellness

- Evidence-Based Design, Healthcare, Hospitality Influence, Materials, Research, User Experience, WELL Building Standard, wellness design

- 1 Comment

It’s that time of the year again, it’s all about new resolutions, wellness, and time for “THE (tedious) annual health checkup”!

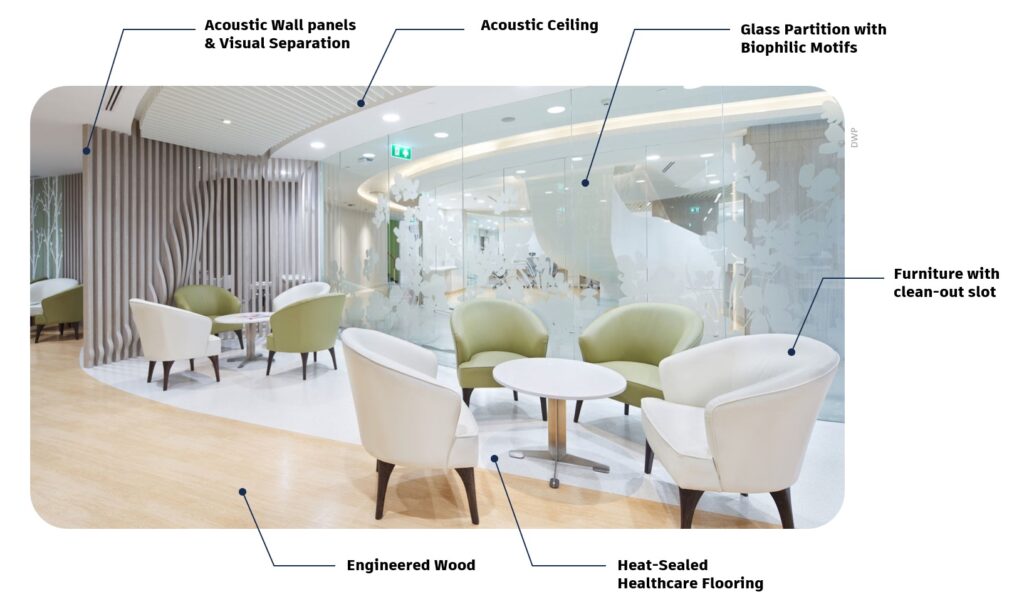

From previous years of this annual ritual in NYC, I was already prepared mentally to probably spend a long day of testing, waiting, and testing again, in the hospital. But I was in for a very pleasant surprise when I arrived at one of Bangkok’s well-known hospitals. The space was so calm and serene. There were entire floors solely dedicated to the annual checkup patients! All processes and testing were done within a few minutes of each other in a highly efficient way with minimum discomfort to patients. The space was welcoming, organized, and efficiently planned to allow for a quick, painless and I might even say pleasant experience.

I often speak about how hospitality and wellbeing design go hand in hand and there are some good examples in Thailand of healthcare facilities that fit into this mold. I find that hospitals that fully embrace the idea of a meticulous blend of healthcare environments with strong hospitality aspects are always much more inviting, relaxing, and pleasant. Asian with specific references to Thai Healthcare facilities have been a fabulous resource for me in my previous experience when working on healthcare projects in the US.

The level of comfort that one feels in a healthcare facility is usually quite low; patients arrive to hospitals distressed and the conventional hospitals setups with all the sounds of people shuffling around, machines, phones ringing, the smells, the stark colors of more the lack of it, tend to increase the patients’ mental distressed state. Many health facilities have endeavored to work towards designs that merge hospitality elements into healthcare environments that lead to a much more welcoming and less stressful ambiance.

In recent years, healthcare spaces have also become highly focused on sustainability and providing better user experiences, with building systems like LEED™ and WELL™. These building systems not only improve the building’s efficiency but the creation of the WELL Building Standard™ provides the first rating system that exclusively focuses on the impacts of buildings on human health and wellness.

The WELL Building Standard™ is particularly interesting in any design project or environment, as its guidelines are based of scientific evidence. In this case, the design environment must be both efficient as well as safe and promote health for the users.

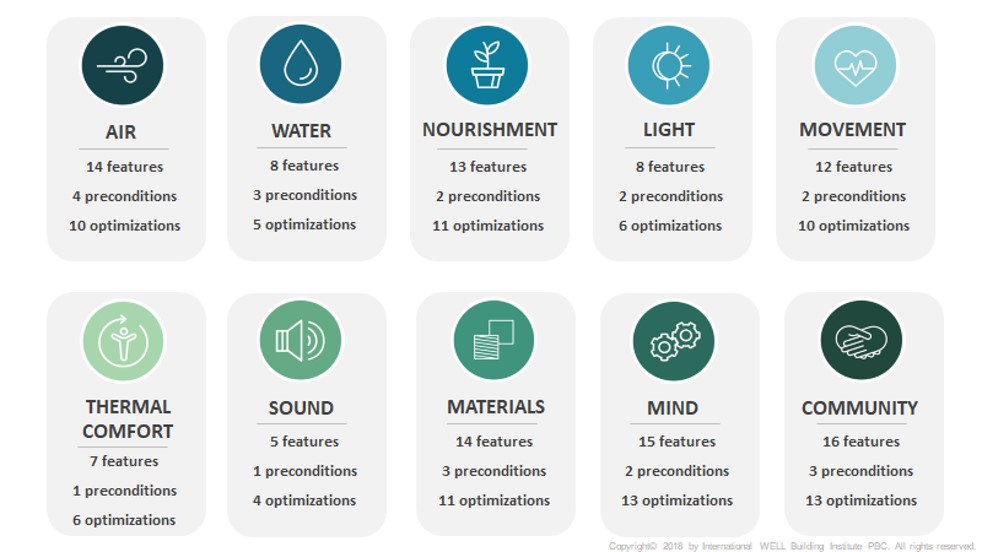

To achieve a successful WELL certification rating, projects must be designed following the guidelines laid out by the design standard. In the latest, Version 2, there are 10 main categories: air, water, nourishment, light, movement, thermal comfort, sound, materials, mind, and community.

Looking around the clinic as I was waiting for the next physical examination, I found myself focused on the materials used in space.

In the WELL Building Standard™, designs must implement the mandatory 3 ‘pre-conditions’ and the optional 8 ‘optimizations’ of the “materials” category.

Pre-conditions:

- X01 Material Restrictions: Restrict Asbestos, Lead, Mercury

- X02 Interior Hazardous Material Management: Manage Asbestos, Lead Paint, and PCB Hazards

- X03 CCA and Lead Management: Manage Exterior Chromate Copper Arsenate (CCA) and Lead Hazards

Optimizations:

- X04 Site Remediation: Safer development of potentially contaminated sites

- X05 Enhanced Material Restrictions: Minimize exposure of certain hazardous chemicals installed in buildings.

- X06 VOC Restrictions: Minimize impact of Volatile Organic Compounds (VOCs) emitted by products into the air.

- X07 Materials Transparency: Provide information transparency of life cycle of building materials and products (HPD/EPD/etc.)

- X08 Materials Optimization: Promote selection of audited products that minimize impacts on human and environmental health.

- X09 Waste Management: Manage environmental contamination and exposures to hazard from certain wastes (batteries, mercury, etc.)

- X10 Pest Management and Pesticide Use: Use integrated pest management (IPM) Principles with non-toxic pest control or pesticides.

- X11 Cleaning Products and Protocols: Provide planned cleaning with less hazardous products (Eco-labels, Green Seal Standard, etc.)

- X12 Contact Reduction: Implement strategies to reduce human contact with respiratory particles and surfaces that may carry pathogens.

It takes quite a lot of work to get into all the breakdowns of every single finish and furniture item that goes into a design, but it is so important to know what’s being placed inside a place. In various project types but especially in healthcare environments, the spaces are subject to constant contact with various organic and hazardous elements. So, using the WELL building standard to assist in the design allows us to create durable spaces that look, perform, and stay maintained brilliantly.

Related Posts

- Geerati Tiasiri

- September 16, 2012

Fire and Life Safety in Bangkok Buildings

From Bangkok Post : “Fico fire spurs sprinkler law for over 1,000 old buildings” A tragic f ..

Michael Simpson

I just could not leave your site prior to suggesting that I actually enjoyed the usual information a person supply to your

visitors? Is gonna be back ceaselessly in order to inspect new posts